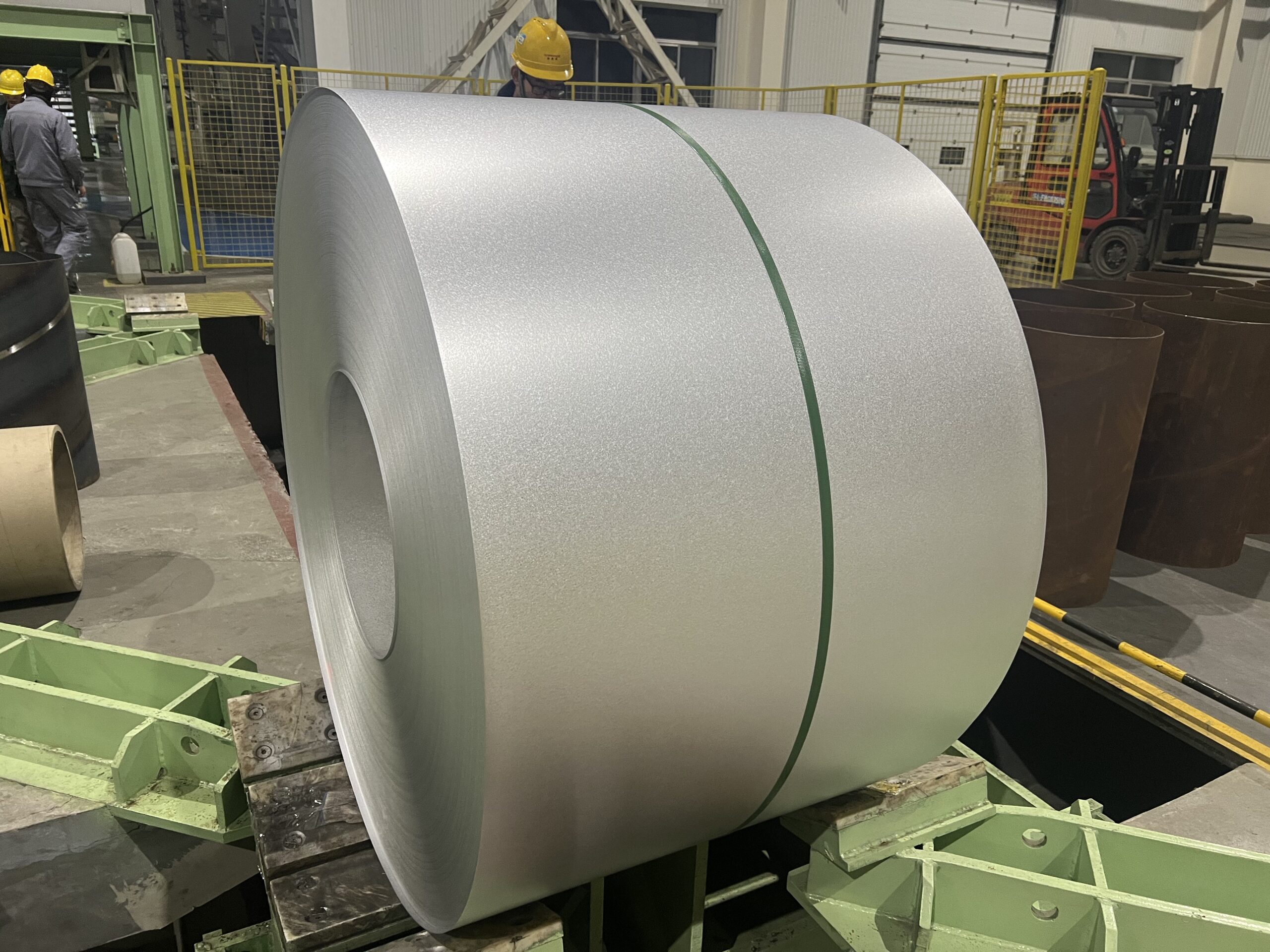

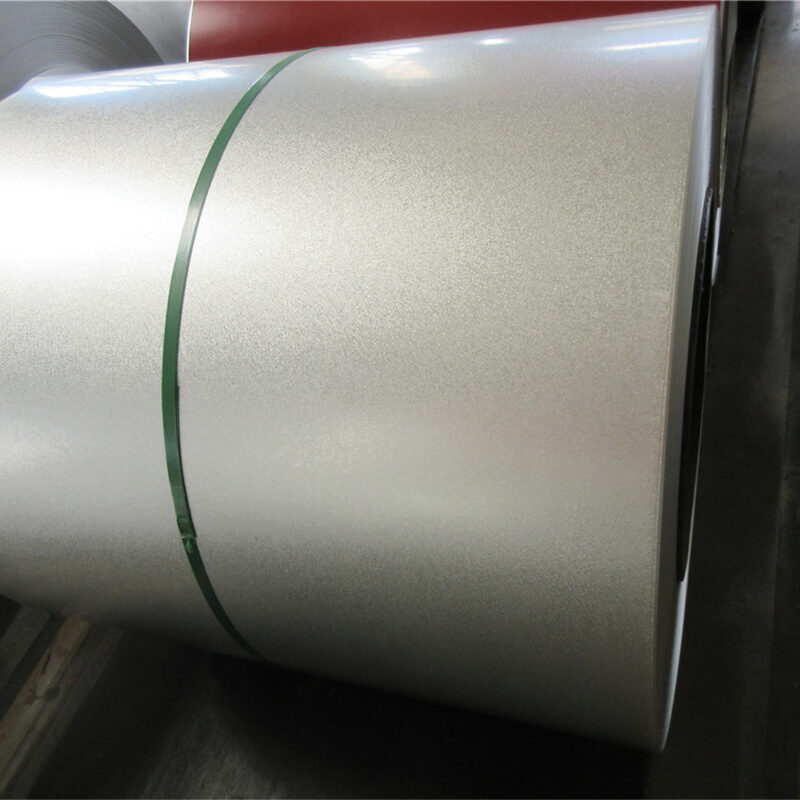

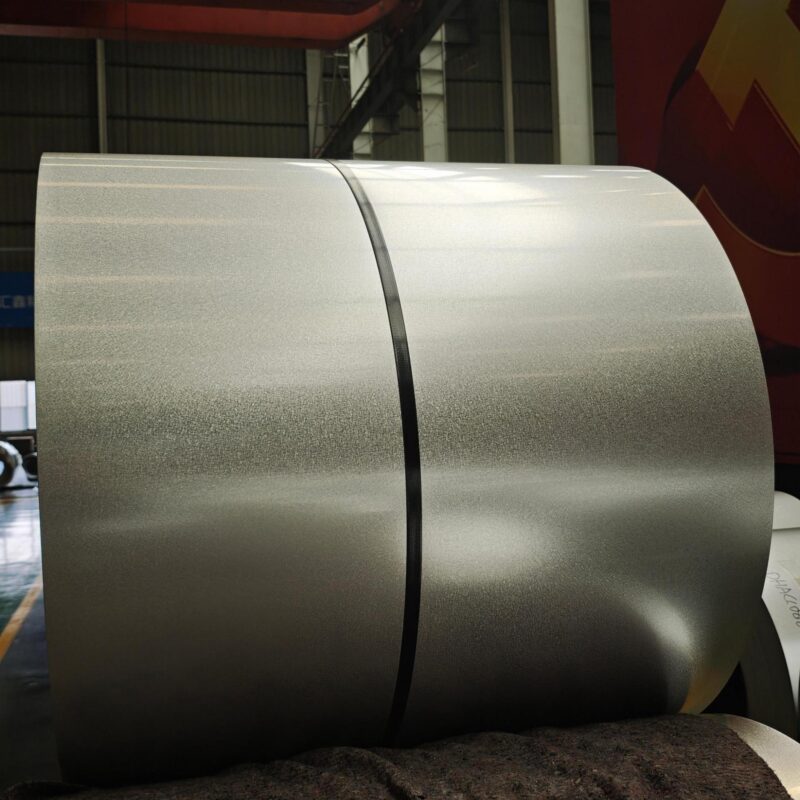

Galvalume steel coil (GL)

Welding Wonders Forging Excellence Together

PRODUCTS DETAIL

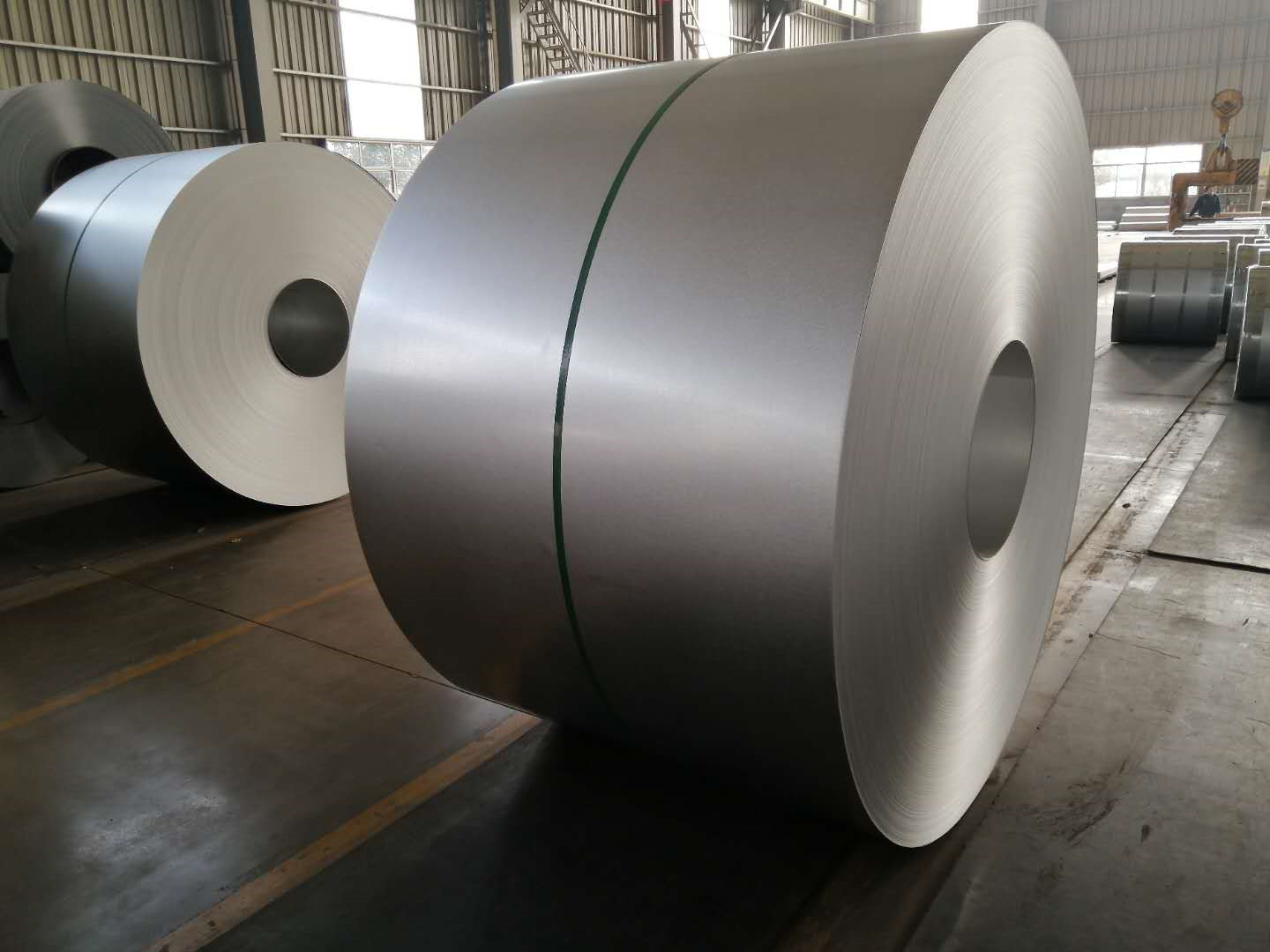

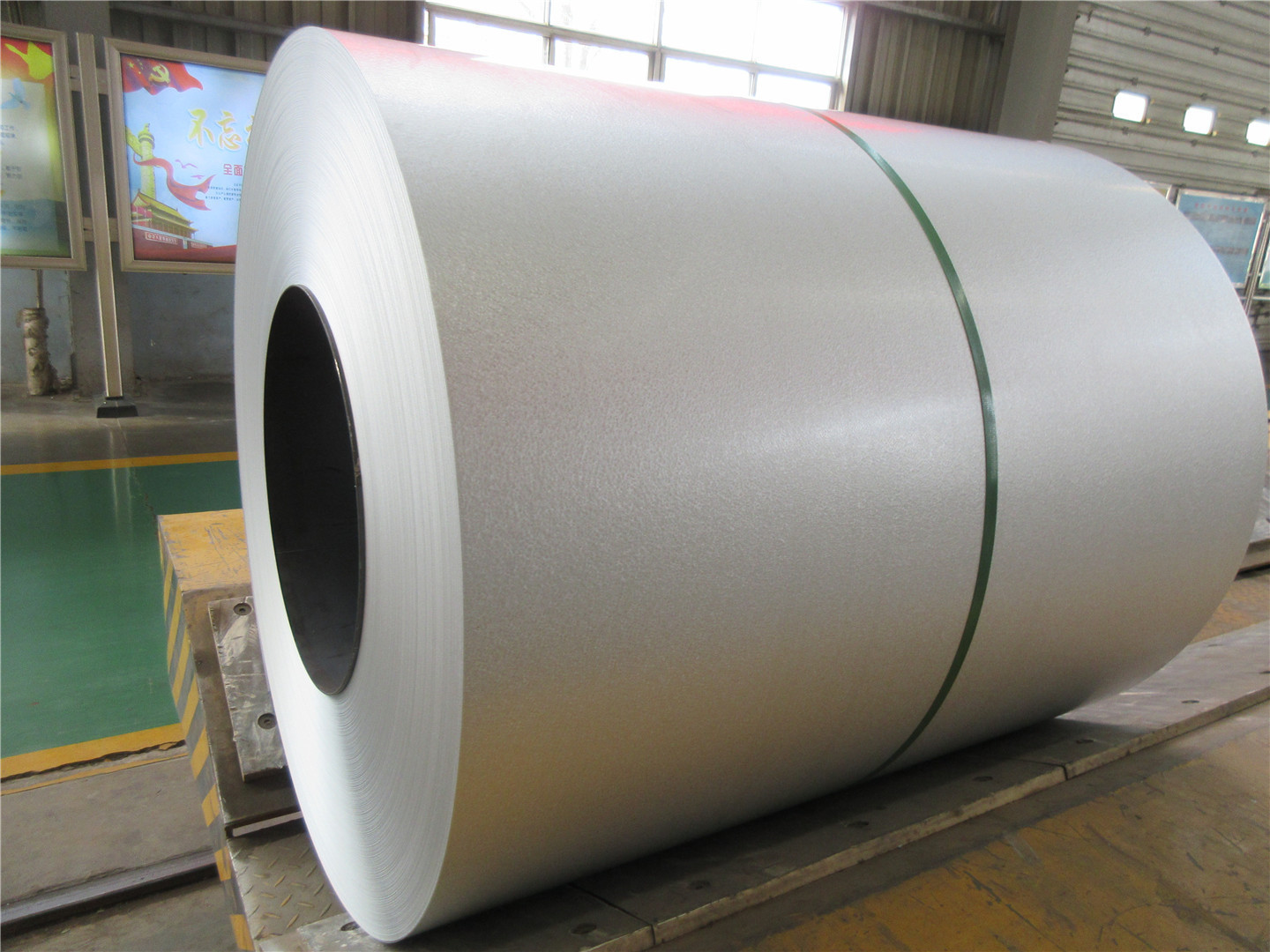

As new building material, galvalume (aluminium&zinc-silicate coated)steel, based upon the cold-rolled steel belt is produced through continuous zinc hot coated technical process by using 55% aluminium,43% zinc and 2% silicate. The coating layer is Zn-Ai alloy.Thanks to the good feature of corrosion resistance, the galvalume steel sheet is 2 to 6 times as high as zinc coated sheet plate in terms of air corrosion resistance with the same coating thickness. With the features of fine coating and processing ability, the product is widely used in the industries of building materials, electric appliance, auto and house hold appliance.etc.

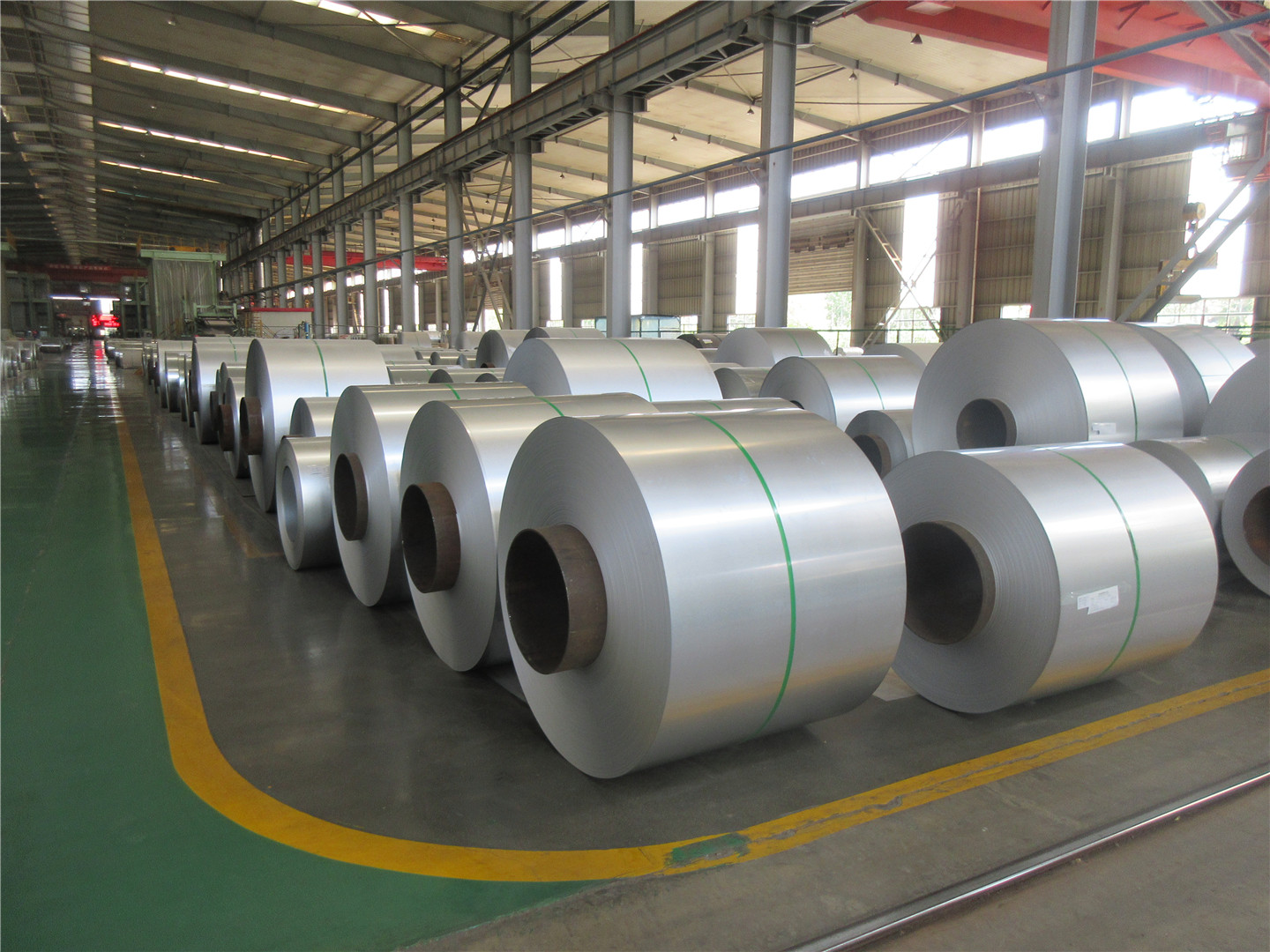

With advanced production line equipment, we can produce ultra thin and high strength galvalume steel sheet, by supplying excellent quality, we enjoys a good reputation both at home and abroad.

Product details

| Item | GL Coil |

| Standard | GB,JIS,ASTM,EN |

| Thickness | 0.13mm-0.8mm |

| Width | 50mm-1500mm |

| Coating | 20g/㎡-275g/㎡ |

| Coil weight | as per your requirements |

| Surface treatment | Oil; Chromated; Oil&Chromated;AFP |

| Package | Standard export package or as your requirements |

Aluminum-zinc Steel Coil Advantages&Features

- Excellent Corrosion Resistance: The aluminum – zinc alloy coating on the surface of aluminized – zinc products has good corrosion resistance. The aluminum element easily forms a dense aluminum oxide film in the air, which can effectively prevent oxygen and moisture from coming into contact with the base metal and prevent rust. For example, in outdoor environments, ordinary steel may show signs of rusting in a short time, while aluminized – zinc steel can still maintain good appearance and performance after years of use.

- Good Heat Resistance: Aluminized – zinc products have good heat resistance and can withstand a certain degree of high temperature. The aluminum – zinc alloy coating can form a stable protective film at high temperatures, which can be used in some occasions that need to withstand high temperatures, such as the automotive exhaust system, which can effectively extend the service life of components.

- High Reflectivity: Aluminized – zinc products have a high reflectivity on the surface, and have a strong ability to reflect light and heat. This characteristic makes it have great advantages in the construction field. It can be used for roof materials, which can effectively reflect sunlight, reduce the indoor temperature, and reduce the energy consumption of refrigeration equipment such as air conditioners, achieving energy conservation and environmental protection.

- Excellent Processing Performance: Aluminized – zinc products have good processing performance and can be subjected to various processing operations such as stamping, bending, and welding to meet the processing needs of different industries. During the processing process, the aluminized – zinc coating is not easy to fall off or be damaged, and can maintain good performance.

- Beautiful Appearance: Aluminized – zinc products have a silver – gray metallic luster on the surface, and the appearance is beautiful and generous. This beautiful appearance makes it widely used in some fields with high requirements for appearance, such as building decoration and home appliance shells, which can enhance the overall grade and market competitiveness of products.

Application Areas

- Construction Industry: It is widely used in building roofs, walls, roof panels, rolling shutter doors, etc. Its corrosion resistance and beauty can make the building appearance last long and beautiful, and at the same time, it can effectively protect the building structure from the erosion of the external environment.

- Home Appliance Industry: It is used for the shells of refrigerators, air conditioners, washing machines and other home appliances. The corrosion resistance and beautiful appearance of aluminized – zinc products can improve the quality and service life of home appliances, and its good processing performance is also convenient for home appliance manufacturers to carry out molding processing.

- Automobile Industry: It can be used for automotive body structural parts, engine hoods, radiator supports and other components. The corrosion resistance and heat resistance of aluminized – zinc products can meet the use requirements of automobiles in different environments, effectively protect automobile components and extend the service life of automobiles.

- Electronics Industry: It is used in the shells and radiators of electronic equipment. The high reflectivity and good heat dissipation performance of aluminized – zinc products are helpful for the heat dissipation of electronic equipment, and its corrosion resistance can also ensure the reliability of electronic equipment in different environments.